Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer's requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don't even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(",").forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can flexible couplings accommodate variable operating conditions and loads?

Yes, flexible couplings are designed to accommodate variable operating conditions and loads in mechanical systems. They offer several features that allow them to adapt to changing conditions and handle different loads effectively. Below are the reasons why flexible couplings are well-suited for such applications:

Misalignment Compensation: Flexible couplings can handle misalignment between shafts, including angular, parallel, and axial misalignment. This capability allows them to accommodate slight shifts in shaft positions that may occur due to thermal expansion, vibration, or other factors, ensuring smooth operation even in changing conditions.

Shock and Vibration Absorption: Flexible couplings can dampen shocks and vibrations that result from sudden changes in load or operating conditions. The flexible element in the coupling acts as a buffer, absorbing and reducing the impact of sudden loads or transient forces, protecting connected equipment and increasing system reliability.

Variable Load Capacity: Flexible couplings come in various designs and materials, each with its load capacity range. Manufacturers provide different coupling models with varying load capacities to accommodate different applications. Properly selecting the right coupling for the specific load conditions ensures reliable power transmission even under varying loads.

Compensation for Thermal Expansion: Temperature changes can cause thermal expansion in mechanical systems, leading to shaft misalignment. Flexible couplings can handle the resulting misalignment, compensating for thermal expansion and ensuring continuous and smooth power transmission.

Torsional Stiffness: Flexible couplings are designed with a balance between flexibility and torsional stiffness. This property allows them to adapt to variable loads while still providing the necessary rigidity for efficient power transmission.

Durable Materials and Designs: Manufacturers produce flexible couplings from durable materials like stainless steel, aluminum, or engineered elastomers. These materials ensure that the couplings can withstand varying operating conditions, including temperature fluctuations, harsh environments, and high loads.

Dynamic Behavior: Flexible couplings have a dynamic behavior that enables them to operate smoothly and efficiently under changing loads and speeds. They can handle variations in rotational speed and torque while maintaining consistent performance.

Application Flexibility: Flexible couplings find applications in a wide range of industries, from automotive and aerospace to industrial and marine. Their versatility allows them to accommodate variable operating conditions and loads in different systems.

Summary: Flexible couplings are well-suited for applications with variable operating conditions and loads. Their ability to compensate for misalignment, absorb shocks and vibrations, and handle thermal expansion make them reliable components in mechanical systems. The availability of various coupling designs and materials allows for the selection of the appropriate coupling based on the specific application requirements, ensuring optimal performance and longevity in variable conditions.

Can flexible couplings be used in power generation equipment, such as turbines and generators?

Yes, flexible couplings are commonly used in power generation equipment, including turbines and generators. These critical components of power generation systems require reliable and efficient shaft connections to transfer power from the prime mover (e.g., steam turbine, gas turbine, or internal combustion engine) to the electricity generator.

Flexible couplings play a vital role in power generation equipment for the following reasons:

- Misalignment Compensation: Power generation machinery often experiences misalignment due to factors like thermal expansion, settling, and foundation shifts. Flexible couplings can accommodate these misalignments, reducing the stress on shafts and minimizing wear on connected components.

- Vibration Dampening: Turbines and generators can generate significant vibrations during operation. Flexible couplings help dampen these vibrations, reducing the risk of resonance and excessive mechanical stress on the system.

- Torsional Shock Absorption: Power generation equipment may encounter torsional shocks during startup and shutdown processes. Flexible couplings can absorb and dissipate these shocks, protecting the entire drivetrain from damage.

- Isolation of High Torque Loads: Some power generation systems may have torque fluctuations during operation. Flexible couplings can isolate these fluctuations, preventing them from propagating to other components.

- Electrical Isolation: In certain cases, flexible couplings with non-metallic elements can provide electrical isolation, preventing the transmission of electrical currents between shafts.

Power generation applications impose specific requirements on flexible couplings, such as high torque capacity, robust construction, and resistance to environmental factors like temperature and humidity. Different types of flexible couplings, including elastomeric, metallic, and composite couplings, are available to meet the varying demands of power generation equipment.

When selecting a flexible coupling for power generation equipment, engineers must consider factors such as the type of prime mover, torque and speed requirements, operating conditions, and the specific application's environmental challenges. Consulting with coupling manufacturers and following their engineering recommendations can help ensure the appropriate coupling is chosen for each power generation system.

How does a flexible coupling impact the overall reliability of connected equipment?

A flexible coupling significantly impacts the overall reliability of connected equipment in several ways:

- Misalignment Compensation: Flexible couplings can accommodate both angular and parallel misalignment between connected shafts. By allowing for misalignment, the coupling reduces the stress and wear on bearings, seals, and other rotating components. This feature prevents premature failure of these components, contributing to improved reliability and extended equipment lifespan.

- Vibration Damping: Flexible couplings possess inherent damping properties due to their elastomeric or flexible elements. These elements absorb and dissipate vibrations generated during the operation of machinery. By dampening vibrations, the coupling protects the connected equipment from excessive oscillations, reducing fatigue and preventing mechanical failures. This enhanced vibration control increases the reliability of the system.

- Shock Load Absorption: In applications with sudden load variations or shock loads, such as in heavy machinery or high-speed equipment, a flexible coupling acts as a shock absorber. It can absorb and dissipate the impact energy, protecting the machinery from damage caused by sudden loads. The ability to absorb shock loads contributes to the overall reliability of the connected equipment.

- Reduced Wear and Tear: The flexibility of the coupling minimizes stress and wear on rotating equipment. It allows for slight movements and misalignments, reducing friction and stress on bearings and other critical components. This reduction in wear and tear lowers the frequency of maintenance and replacement, increasing the overall reliability of the equipment.

- Compensation for Thermal Expansion: Temperature changes in machinery can lead to thermal expansion or contraction of shafts. A flexible coupling can compensate for these thermal effects, ensuring that the machinery remains properly aligned even as temperature conditions fluctuate. This compensation prevents binding and misalignment, promoting reliable performance.

- Protection Against Overloads: Flexible couplings help protect connected equipment from overloads and torsional vibrations. They act as a mechanical fuse, disconnecting the driveline when an overload occurs, thus preventing damage to expensive machinery. This safety feature enhances the overall reliability and reduces the risk of catastrophic failures.

- Easy Maintenance and Alignment: Flexible couplings are designed for easy installation and alignment. This feature simplifies maintenance procedures, making it easier to inspect and replace couplings when necessary. Properly aligned couplings lead to improved equipment performance and longevity, enhancing overall reliability.

By compensating for misalignment, damping vibrations, absorbing shock loads, reducing wear and tear, and providing other protective features, a flexible coupling significantly improves the reliability of connected equipment. It extends the lifespan of critical components, minimizes downtime, and ensures smooth and efficient operation, making it a valuable component in various industrial applications.

editor by CX 2024-04-03

China best Sintered Alloy Iron/Copper-Iron CNC Machinery Auto Car Motorcycle Electrical Tools Textile Engine Gearbox Transmission Reducer Flexible Shaft Jaw Coupling

Product Description

Excellent powder metallurgy parts metallic sintered parts

We could offer various powder metallurgy parts including iron based and copper based with top quality and cheapest price, please only send the drawing or sample to us, we will according to customer's requirement to make it. if you are interested in our product, please do not hesitate to contact us, we would like to offer the top quality and best service for you. thank you!

How do We Work with Our Clients

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don't even need to know what casting is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

| Place of origin: | Jangsu,China |

| Type: | Powder metallurgy sintering |

| Spare parts type: | Powder metallurgy parts |

| Machinery Test report: | Provided |

| Material: | Iron,stainless,steel,copper |

| Key selling points: | Quality assurance |

| Mould type: | Tungsten steel |

| Material standard: | MPIF 35,DIN 3571,JIS Z 2550 |

| Application: | Small home appliances,Lockset,Electric tool, automobile, |

| Brand Name: | OEM SERVICE |

| Plating: | Customized |

| After-sales Service: | Online support |

| Processing: | Powder Metallurgr,CNC Machining |

| Powder Metallurgr: | High frequency quenching, oil immersion |

| Quality Control: | 100% inspection |

The Advantage of Powder Metallurgy Process

1. Cost effective

The final products can be compacted with powder metallurgy method ,and no need or can shorten the processing of machine .It can save material greatly and reduce the production cost .

2. Complex shapes

Powder metallurgy allows to obtain complex shapes directly from the compacting tooling ,without any machining operation ,like teeth ,splines ,profiles ,frontal geometries etc.

3. High precision

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered,improvable up to IT 5-7 after sizing .Additional machining operations can improve the precision .

4. Self-lubrication

The interconnected porosity of the material can be filled with oils ,obtaining then a self-lubricating bearing :the oil provides constant lubrication between bearing and shaft ,and the system does not need any additional external lubricant .

5. Green technology

The manufacturing process of sintered components is certified as ecological ,because the material waste is very low ,the product is recyclable ,and the energy efficiency is good because the material is not molten.

FAQ

Q1: What is the type of payment?

A: Usually you should prepay 50% of the total amount. The balance should be pay off before shipment.

Q2: How to guarantee the high quality?

A: 100% inspection. We have Carl Zeiss high-precision testing equipment and testing department to make sure every product of size,appearance and pressure test are good.

Q3: How long will you give me the reply?

A: we will contact you in 12 hours as soon as we can.

Q4. How about your delivery time?

A: Generally, it will take 25 to 35 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. and if the item was non standard, we have to consider extra 10-15days for tooling/mould made.

Q5. Can you produce according to the samples or drawings?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6: How about tooling Charge?

A: Tooling charge only charge once when first order, all future orders would not charge again even tooling repair or under maintance.

Q7: What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q8: How do you make our business long-term and good relationship?

A: 1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

How does a flexible coupling help in power transmission efficiency?

Flexible couplings play a crucial role in improving power transmission efficiency in various mechanical systems. Here are the ways in which flexible couplings contribute to enhanced efficiency:

- Misalignment Compensation: In real-world applications, it is challenging to achieve perfect alignment between shafts due to manufacturing tolerances, thermal expansion, or external forces. Flexible couplings can accommodate both angular and parallel misalignments between the driving and driven shafts. By doing so, they ensure that the torque is transmitted smoothly and efficiently despite misalignment, reducing power losses due to misaligned shafts.

- Vibration Damping: Vibrations in mechanical systems can lead to energy losses and premature wear of components. Flexible couplings with vibration-damping properties can absorb and dampen vibrations generated during operation. By reducing the transmission of vibrations, these couplings help to maintain power transmission efficiency and extend the lifespan of connected equipment.

- Shock Load Absorption: During start-up or sudden changes in operating conditions, equipment may experience shock loads. Flexible couplings are designed to absorb and cushion these shock loads, preventing sudden impacts on the system. By minimizing the shock load's effect, flexible couplings contribute to smoother power transmission and reduced stress on components.

- Torsional Stiffness: While flexible couplings allow for misalignment compensation, they still exhibit a certain degree of torsional stiffness. This stiffness ensures that the majority of the torque is efficiently transmitted from the driving to the driven shaft, minimizing power losses due to deformation or bending of the coupling.

- Reduced Friction and Wear: Flexible couplings typically have a simple design with fewer moving parts. This simplicity leads to reduced friction and wear compared to more complex coupling types. Lower friction means less energy dissipation, resulting in improved power transmission efficiency.

- Compatibility with Various Applications: Flexible couplings come in a wide range of designs and materials to suit different applications. Whether it's high-speed machinery, heavy-duty equipment, or precision systems, there are flexible coupling options optimized for each use case. Selecting the appropriate coupling for the specific application ensures efficient power transmission.

In summary, flexible couplings enhance power transmission efficiency by compensating for misalignment, damping vibrations, absorbing shock loads, providing torsional stiffness, reducing friction and wear, and offering compatibility with diverse applications. The combination of these features contributes to improved overall system efficiency and helps optimize the performance of mechanical systems.

What are the factors influencing the thermal performance of a flexible coupling?

The thermal performance of a flexible coupling can be influenced by several factors, including:

- Material Composition: The material used in the construction of the flexible coupling can impact its thermal performance. Different materials have varying thermal conductivity and heat resistance properties, which can affect how well the coupling dissipates heat generated during operation.

- Operating Speed: The rotational speed of the flexible coupling can influence its thermal behavior. Higher speeds can result in increased friction, leading to more heat generation. Couplings designed for high-speed applications often incorporate features to manage and dissipate heat effectively.

- Power Transmission: The amount of power transmitted through the flexible coupling plays a role in its thermal performance. Higher power levels can lead to increased heat generation, and the coupling must be designed to handle and dissipate this heat without compromising its integrity.

- Environmental Conditions: The ambient temperature and surrounding environment can impact the thermal performance of the flexible coupling. In high-temperature environments, the coupling may need to dissipate heat more efficiently to avoid overheating.

- Lubrication: Proper lubrication is essential for managing friction and heat generation within the coupling. Insufficient or inappropriate lubrication can lead to increased wear and heat buildup.

- Design and Geometry: The design and geometry of the flexible coupling can influence its thermal performance. Some coupling designs incorporate features such as cooling fins, ventilation, or heat sinks to enhance heat dissipation.

- Load Distribution: The distribution of loads across the flexible coupling can affect how heat is generated and dissipated. Proper load distribution helps prevent localized heating and reduces the risk of thermal issues.

Manufacturers consider these factors during the design and selection of flexible couplings to ensure they can handle the thermal demands of specific applications. Proper application and maintenance of the flexible coupling are also essential for optimizing its thermal performance and overall efficiency.

How does a flexible coupling protect connected equipment from shock loads and vibrations?

Flexible couplings play a crucial role in protecting connected equipment from shock loads and vibrations by providing damping and isolation capabilities. When machines or mechanical systems experience sudden shock loads or vibrations, the flexible coupling acts as a buffer, absorbing and dissipating the impact, thereby reducing the transmitted forces and protecting the equipment. Here's how flexible couplings achieve this:

- Damping of Vibrations: Flexible couplings are often made from materials that exhibit damping properties. When vibrations are transmitted through the shafts, the flexible coupling's material can absorb a portion of the vibrational energy, converting it into heat. This dissipation of energy helps reduce the amplitude of the vibrations and prevents them from propagating further into the connected equipment.

- Vibration Isolation: In addition to damping vibrations, flexible couplings also offer a degree of vibration isolation. They are designed to decouple the two shafts, which means that vibrations occurring on one shaft are not directly transmitted to the other shaft. This isolation effect prevents vibrations from propagating across the entire system and minimizes the impact on sensitive equipment or nearby components.

- Shock Absorption: When the connected machinery experiences sudden shock loads, such as during a startup or abrupt changes in load, the flexible coupling can act as a shock absorber. The coupling's design allows it to deform slightly under the impact, absorbing and distributing the shock energy. This prevents the shock from being directly transferred to the connected equipment, reducing the risk of damage or premature wear.

- Misalignment Compensation: Flexible couplings are capable of compensating for misalignment between the shafts. Misalignment can lead to additional stresses and vibrations in the system. By allowing for some degree of angular, parallel, and axial misalignment, the flexible coupling reduces the forces transmitted to the connected equipment and the supporting structures.

- Reduction of Resonance Effects: Resonance is a phenomenon that occurs when the natural frequency of a system matches the frequency of external vibrations, leading to amplified vibrations. Flexible couplings can help avoid resonance effects by altering the system's natural frequency and providing some level of flexibility that damps the resonance response.

By incorporating a flexible coupling into the drivetrain or power transmission system, equipment manufacturers and operators can significantly improve the reliability and longevity of connected machinery. The coupling's ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more stable operation, reducing maintenance requirements and enhancing overall system performance.

In summary, flexible couplings act as protective elements, shielding connected equipment from shock loads and vibrations. Their ability to dampen vibrations, isolate shocks, and compensate for misalignment contributes to a smoother and more reliable operation of various mechanical systems.

editor by CX 2023-10-06

Best China manufacturer & factory worm in Irkutsk Russian Federation gearbox XG TA shaft mounted hanging gearbox speed reducer for mining & quarry vertical gearbox with motor speed variator With high quality best price

EPG is 1 of the largest producers in China. We have advanced machines for generation and new technological innovation tests capacity . By way of adopting new technologies from British, German, U.S.A, our items are very best sellers all more than European, The us, and Southeast Asia.

Overview

Rapid Information

- Applicable Industries:

-

Creating Substance Retailers, Manufacturing Plant

- Gearing Arrangement:

-

Helical

- Output Torque:

-

137~9800 N.m

- Enter Pace:

-

1400rpm

- Output Speed:

-

forty six~280RPM

- Spot of Origin:Zhejiang, China

- Manufacturer Name:

-

OEM

- Coloration:

-

Blue / Gray / Consumer need

Supply Capability

- Offer Potential:

- 2000 Established/Sets per Month

Packaging & Shipping and delivery

- Packaging Information

- wooden Case for every laptop + several pcs in picket scenario

- Port

- Chinese Port

-

Lead Time

: -

Quantity(Boxes) one - 12 >12 Est. Time(times) twelve To be negotiated

Online Customization

Movie Description

Specification

XG / TA shaft mounted hanging gearbox velocity reducer

Conveyor & Substance Handling

Mining & Quarry

|

SLXG Shaft Mounted Reducer |

Output Shaft Bore [mm] |

Ratio(i) |

Rated torque |

|

SLXG30 |

Φ30 |

7, ten, 12.5 |

180N.m |

|

SLXG35 |

Φ35 |

5,ten,fifteen,20,twenty five |

420N.m |

|

SLXG40 |

Φ40 |

five,ten,12.5,fifteen,twenty,25 |

900N.m |

|

Φ45 |

|||

|

SLXG45 |

Φ45 |

five,10,12.5,15,20,twenty five |

1400N.m |

|

Φ50 |

|||

|

Φ55 |

|||

|

SLXG50 |

Φ50 |

five,ten,12.5,fifteen,20,25 |

2300N.m |

|

Φ55 |

|||

|

Φ60 |

|||

|

SLXG60 |

Φ60 |

5,ten,twelve.5,fifteen,20,twenty five |

3600N.m |

|

Φ70 |

|||

|

SLXG70 |

Φ70 |

5A pace reducer, usually referred to as a gear box, is an enclosed mechanical gadget that utilizes gearing to reduce speeds and improve torque on a push. A worm equipment reducer, or worm gearbox, is the most typically discovered velocity reducer. Generally a worm gear reducer will be mounted or coupled to an electrical motor. Worm equipment reducers are available in a wide array of designs, configurations and ratio’s. Worm equipment reducers are used in all industries, and arrive in dimensions from a few kilos to numerous tons for large industrial purposes. ,10,12.5,15,20,25,31 |

5100N.m |

|

Φ85 |

|||

|

SLXG80 |

Φ80 |

5,ten,12.5,fifteen,20,twenty five,31 |

7000N.m |

|

Φ100 |

|||

|

SLXG100 |

Φ100 |

five,10,12.5,15,twenty,25,31 |

11000N.m |

|

Φ125 |

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery slicing equipment. |

PTO shaft connectors on tractors are not standardized which can lead to difficulties when connecting the PTO shaft. For instance, some more mature tractor models have the connection flange nearer to the tractor by itself generating it hard to link and lead to a potential protection hazard.

Associated product

Company Profile

Packing & Supply

Best China manufacturer & factory 202N.m in Makhachkala Russian Federation single cycloidal reduction drive reducer cycloidal BL2 vertical gearbox With high quality best price

Provider & Top quality controlWe supply thorough drawings and offer you each time necessary.

Overview

Swift Specifics

- Applicable Industries:

-

Producing Plant

- Brand Title:

-

OEM

- Item NO:

-

SYF

- Colour:

-

Buyer Necessity

- Bearing:

-

NSK Bearing

EPG specializing in the manufacture of rotocultivator ploughshares and other non-standardized farm machinery slicing equipment.

- Ratio:

-

eleven~87

- Mounting Placement:

-

Horizontal and Vertical

- Output torque:

-

two.6-1195N.M

- Output velocity:

-

.16-1028r/min

- Content:

-

Cast Iron

- Warranty:

-

one-2 Several years

Packaging & Supply

-

Share-keeping in other manufacturing firms (i.e. EPG and HPT ), buying and selling companies and support firms, as nicely as significant industrial partnerships, generate an perfect distribution of competences enabling higher specialization and extreme rapidity in the management of inquiries. This organisation tends to make us an all-embracing, functional and highly experienced supplier in the planet of movement drives. Direct Time

: -

Quantity(Items) one - one 2 - five >5 Est. Time(days) 3 12 To be negotiated

On the web Customization

Item Description

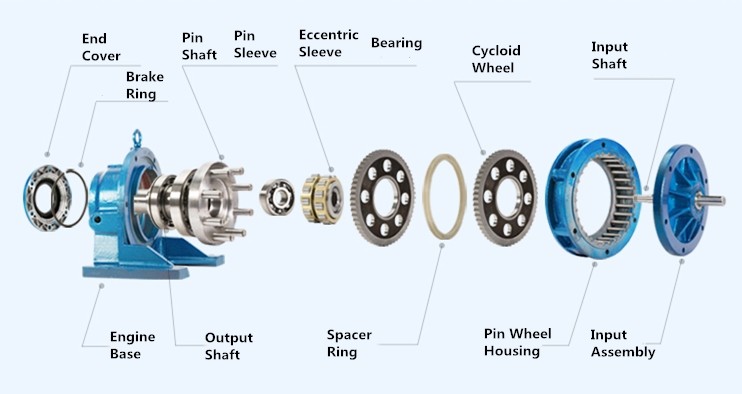

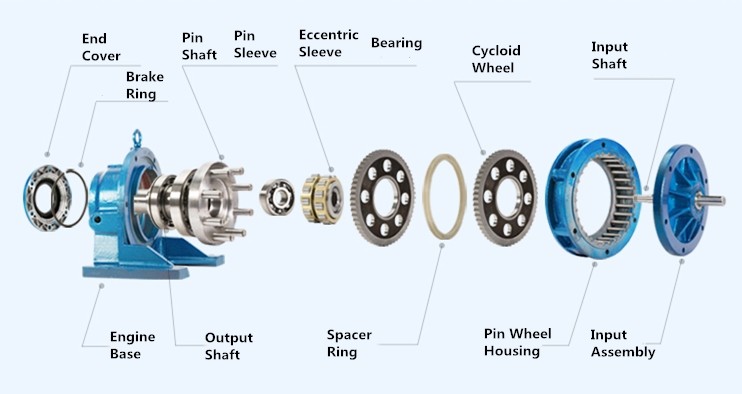

Cycloidal Pin Wheel Reducer

Cycloidal equipment reducer has sound shaft output, hollow shaft output and agreement disk hollow shaft output,which can be mounted horizontally , vertically. Cycloidal Gearbox is created of high energy quality alloy metal by means of quenching and possesses high efficiency and long existence gear .Othermore,Cycloidal gear reducer can bear big axial and radial load.Attributes is minimal in run noise, higher in trustworthiness, compact and so on.

|

Dimension |

X1 |

X2 |

X3 |

X4 |

X5 |

X6 |

X7 |

X8 |

X9 |

|||||||||

|

B09 |

B0 |

B1 |

B2 |

B3 |

B4 |

B5 |

B6 |

|||||||||||

|

Output Torque N.M |

||||||||||||||||||

|

Pace Ratio |

Enter Speed 1500 rpm |

one thousand rpm |

||||||||||||||||

|

11 |

26 |

forty eight.three |

141.seven |

257.six |

483. |

708.three |

965.nine |

1787. |

2125.1 |

|||||||||

|

17 |

40 |

74.6 |

149.3 |

398.one |

746.four |

1094.7 |

1492.eight |

2761.8 |

3284.three |

|||||||||

|

23 |

27 |

fifty three.nine |

202. |

296.two |

740.five |

1481.8 |

1481.eight |

3736.five |

3736.5 |

|||||||||

|

29 |

34 |

sixty seven.nine |

186.7 |

373.five |

933.seven |

1867.4 |

1867.4 |

2546.five |

4711.three |

|||||||||

|

35 |

forty one |

eighty two |

225.four |

307.four |

819.six |

1536.7 |

2253.8 |

3673.four |

5686.five |

|||||||||

|

forty three |

50 |

a hundred.seven |

151. |

377.6 |

755.two |

1384.5 |

1887.9 |

2768.9 |

3775.eight |

|||||||||

|

fifty nine |

207.2 |

380. |

759.9 |

1381.5 |

1899.6 |

2590.four |

3799.3 |

|||||||||||

|

seventy one |

166.three |

332.5 |

623.5 |

1246.nine |

1662.5 |

2286. |

4572. |

|||||||||||

|

87 |

280.one |

764. |

1120.5 |

2037.2 |

2037.2 |

7639.5 |

||||||||||||

THICKENING Base

The box entire body is made of HT200 substance,which is cleaned by expert screening and washing products to ensure that the internal cavity of the box human body is cleaner without iron filings.

REDUCER SHAFT

New national standard shaft.

Multi-precision machining, through rigid dynamic and static harmony test techniques, to guarantee the reducer managing low sounds, equilibrium easy.

Professional AIR TIGHTNRSS Test

Semi-Computerized PET Bottle Blowing Machine Bottle Making Device Bottle Moulding Device

PET Bottle Making Machine is suited for generating PET plastic containers and bottles in all styles.

Cycloid wheel

The cycloid wheel hardened bearing metal,

higher strength, long provider daily life of the rolling friction get in touch with elements adopt.

Item Traits

Higher Pace Ratio and Substantial Effectiveness

Solitary-stage transmission can achieve a deceleration ratio of 1:87, and the effectiveness is above 90%. If multi-stage transmission, the deceleration ratio is bigger.

Compact framework and little quantity

Since the planetary transmission theory is adopted, the input shaft and the output shaft are on the identical axis, so the composition is compact and the volume is little.

Sleek procedure and reduced noise

Cycloidal pin enamel have many meshing enamel, huge overlap coefficient and sleek system, which restrictions vibration and sound to a least.

Trustworthy use and prolonged service lifestyle

Simply because the principal elements are bearing metal, substantial energy is obtained by quenching remedy (HRC58-sixty two), and rolling friction is utilised in some transmission contacts, which is resilient and has lengthy service lifestyle.

Our Company

HANGZHOU Ever-Power Group, 1 OF THE Most significant GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Gear Provide STATION

Our organization is situated in the town of HangZhou, ZheJiang Province of China.

We take care of the products of energy transmission, our strains primarily protect sequence merchandise in pace reducers, gearboxes , related electricial motors and other electrical power transmission equipment. Primarily based on the versatile capabilities, our merchandise can be used in numerous fields: machines of squander h2o treatment, dredgers, chemical business, cranes, steel working mills, conveyors, paper market, cement business, cableways and so on.With the superb quality and sensible price , our merchandise appreciate a very good popularity from clients and the friends all more than the planet.

Moreover, the R&D investment decision are every year escalating for the function of better assembly the new demands of our consumers and adapting the new inclination of the business.

Depending on the ideas of truthfully functioning and mutual gain, We sincerely appear forward to cooperating with you.

Software location

Certifications

Packing&Transportion

FAQ

Q1: Are you a buying and selling comOur PTO generate shafts permit the consumer effortless routine maintenance. The greasing nipples on common crosses are positioned underneath angle to enable the user much better entry. Easier obtain is also feasible since of the versatile cone. We listened to the needs of our buyers and placed the greasing nipple at extensive-angle PTO’s into the cross bearing. The other novelty, we launched with broad-angle PTO push shafts is in line greasing. We wished to moreover simplify the upkeep and lengthen the lifespan of joints.pany or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our organization owns the capability of producing, processing,designing and R&D. We welcome your check out.

Q2: How we pick designs and specs?

A: In accordance to the specific information of the requires from the part of enquiry, we will recommend the products' designs on synthesizing the factors of field of products use, energy, torque arm and ratio...

Q3: How is your value? Can you offer you any discount?

A: Our costs are constantly competitive. If the buyer can area a huge order, we certainly will allow low cost.

This autumn: How long should I hold out for the opinions after I send the enquiry?

A4: We will reply the enquiries with no any delay, twelve hrs at most.

Q5: What is your item warranty time period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes being utilised?

A: Our gearboxes are widely used to metallurgical gear, mining gear, automation gear, foodstuff equipment, packaging gear, tobacco tools and so on.

Relevant Merchandise